Motor load & electrical insight

Three split-core CTs capture per-phase current so you can see loading, imbalance, inrush behavior, and overload conditions in real time—right where maintenance needs it.

M3 is built for industrial sites like grain elevators, feed mills, and manufacturing plants. It continuously measures 3-phase current, vibration, and temperature and alerts your maintenance team when a motor starts drifting toward failure—before downtime hits production.

M3 is intended for permanent equipment inside facilities—motors that drive conveyors, augers, fans, pumps, mixers, and process lines.

Bring industrial-grade monitoring and early-warning analytics to critical motors across grain handling and factory-floor equipment—without replacing existing controls.

Three split-core CTs capture per-phase current so you can see loading, imbalance, inrush behavior, and overload conditions in real time—right where maintenance needs it.

Track bearing/shaft signatures and trending. Detect early mechanical issues on conveyors, augers, fans, and pumps—before failures become shutdowns.

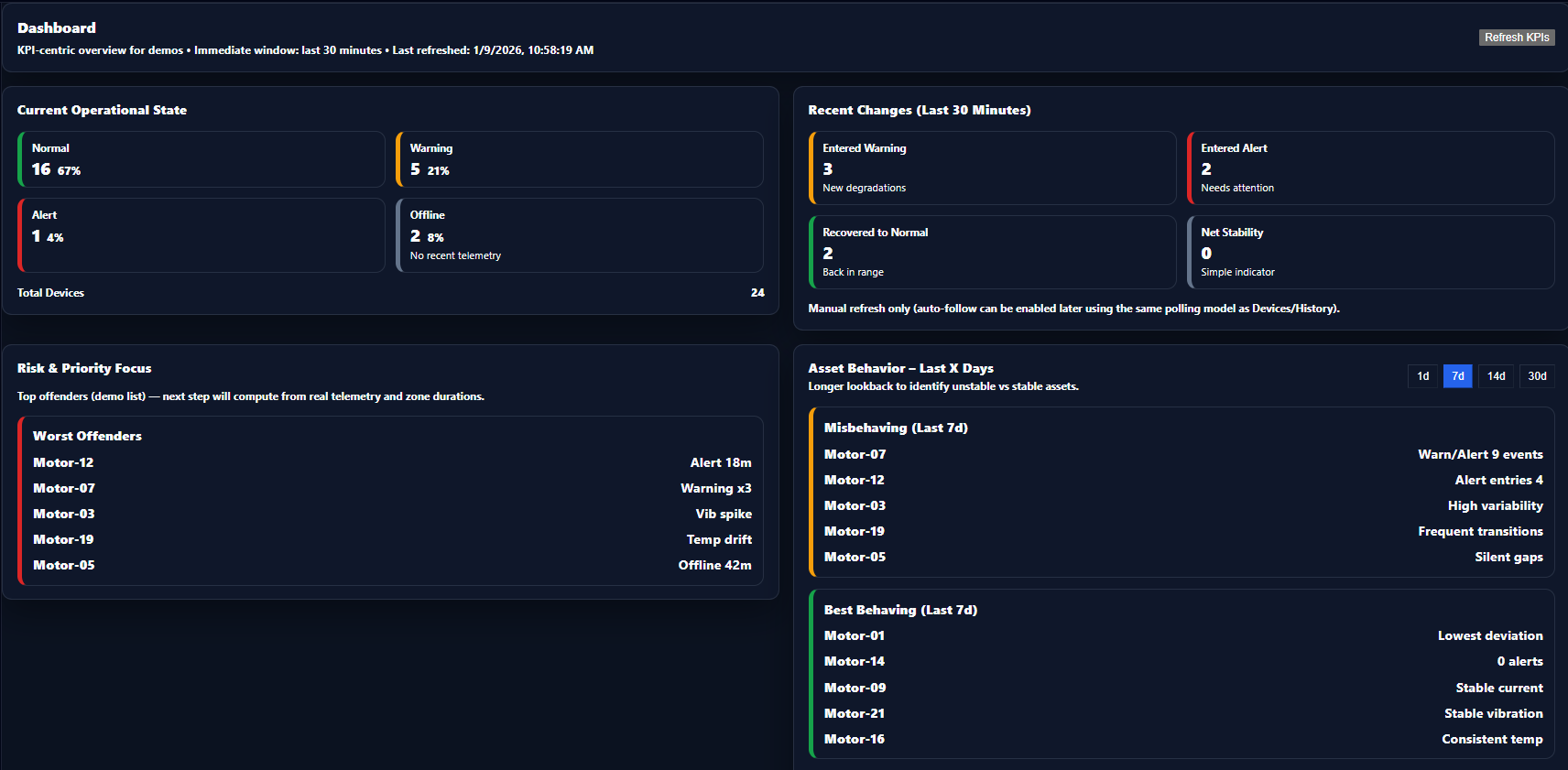

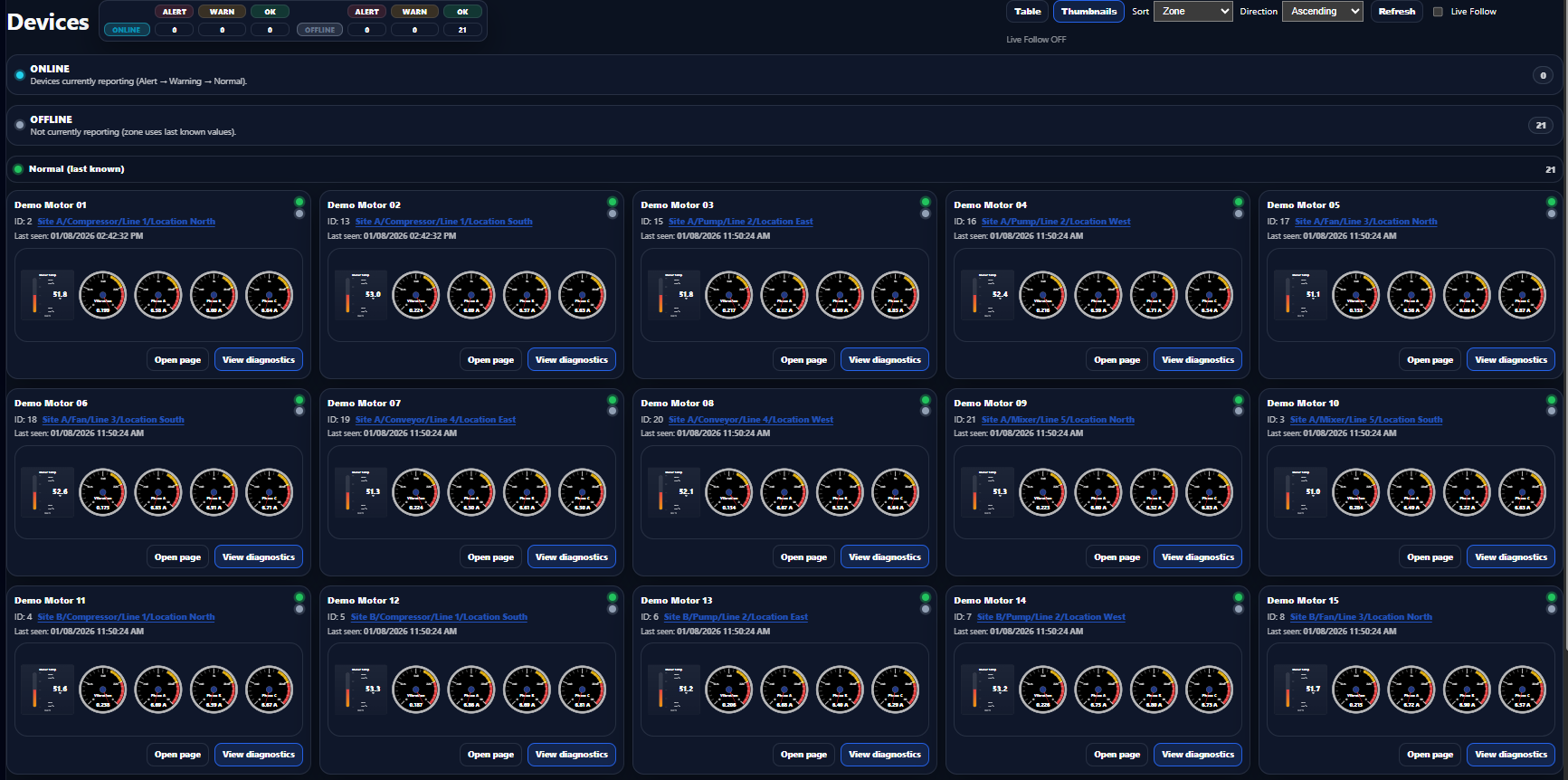

Designed for maintenance, reliability, and controls. Clear alarms, thresholds, and dashboards that match how fixed sites operate.

M3 is designed for motors installed in facilities—driving process equipment and material handling. Typical deployments include:

Bucket elevators, conveyors, drag chains, augers, and distributor drives—monitor load and vibration as conditions change with product flow.

Mixers, grinders, fans, and pumps—catch bearing wear, misalignment, and overheating early to protect throughput and uptime.

Compressors, exhaust/air-handling, packaging lines, and conveyors—standard site dashboards and alarm routing for maintenance teams.

M3 is purpose-built for stationary industrial motors installed in agriculture sites and manufacturing facilities. The platform is designed for fixed equipment inside facilities and is not intended for mobile or transportation applications.

Permanent installations: grain elevators, feed mills, processing plants, and factories. M3 focuses on motor health, maintenance workflows, and site-level dashboards.

M3 is not marketed for vehicles, mobile assets, or rolling equipment. The platform is engineered specifically for fixed-site industrial environments.

Current + vibration + temperature with clear thresholds, alerts, and trends—so technicians can plan service before a motor becomes downtime.

A single dashboard for maintenance, reliability, and operations to see motor health across your site at a glance.

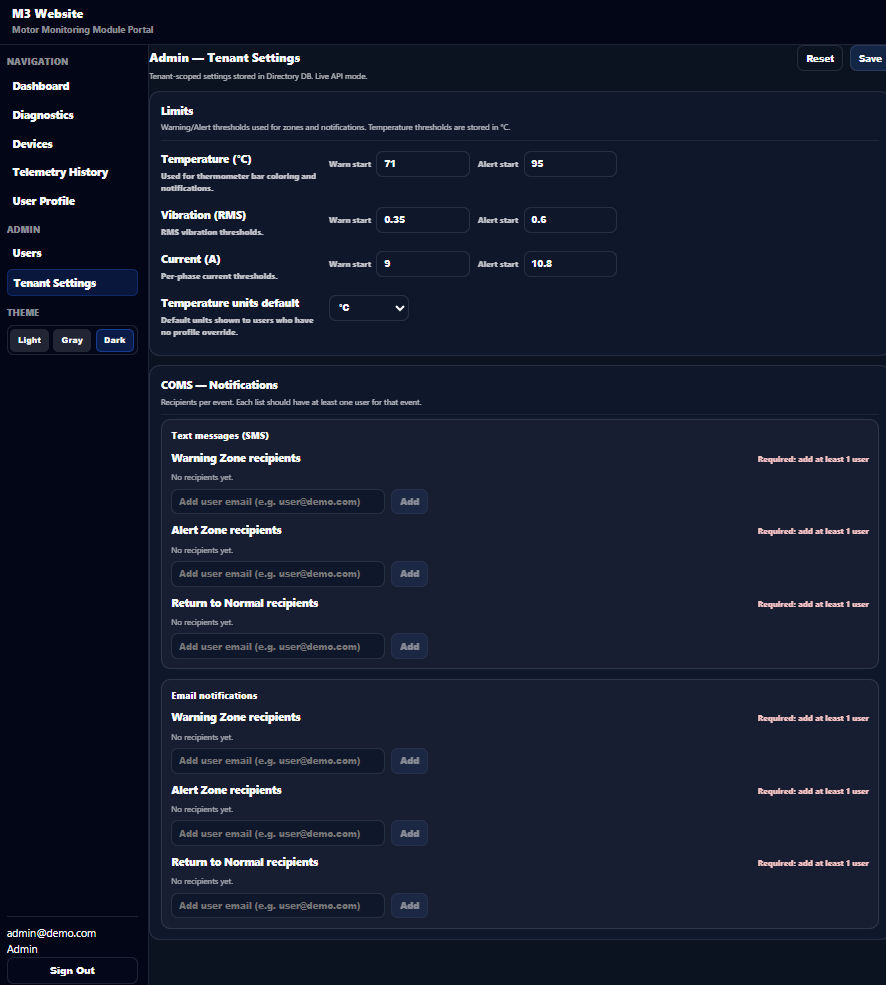

Configure over-current, over-temp, vibration, and anomaly thresholds. Preview trip delays and auto-restart behavior to balance uptime and protection.

Keep marketing aligned with the real product UI by dropping updated images into marketing/assets/.

M3 drops into existing MCCs or local disconnects, drives a standard 12/24 V contactor coil, and connects over Wi-Fi to your site or cloud.

• 3-phase 480 VAC motor circuits (monitored)

• Split-core CTs (non-intrusive)

• External contactor coil output (12/24 V)

• Line-powered with backup for graceful outages

• Current, vibration (3-axis MEMS), and temperature

• RMS + FFT vibration analysis at the edge

• Baseline learning per motor (anomaly detection)

• Configurable sample and telemetry rates

• Wi-Fi TLS to M3 cloud or your endpoint

• REST / MQTT APIs for OT, MES, or CMMS

• Site dashboards and alarm routing

• Designed for harsh industrial environments

Tell us about your site and equipment. We’ll help you pick a pilot area, define alarm rules, and stand up a monitoring dashboard in days—not months.

Prefer email? info@m3monitor.com

M3 Monitor is a fixed-site agricultural and industrial motor monitoring platform designed to provide real-time visibility into motor health using vibration, current, and temperature analytics.

M3 Monitor was founded and is operated by Joseph Zangara, an engineering leader with extensive experience in industrial systems, embedded electronics, test engineering, and software platforms for mission-critical applications.

The platform is currently under active development and pilot deployment, with a focus on predictive maintenance, early fault detection, and operational reliability for industrial customers.

Founder & Authorized Representative:

Joseph Zangara

Founder, M3 Monitor

Contact: joe.zangara@m3monitor.com